Designing parts for plastic injection is a requirement for many manufacturing companies. It does not need to be a difficult one. Plastic injection molding is one of the most used forms of production in the United States, as everything from car designers to food packaging companies use some form of plastic injection. It really just comes down to understanding how to design the product and what it takes to do so. The injection molding company can work with a computer aided design (CAD) professional to make sure everything is properly formulated on the computer, which in turn makes the production process that much easier.

Initial Design Process

First, the initial design of the part takes place. During these early stages of plastic parts design, the manufacturing company is going to determine all of the dimensions the part needs to be, how it needs to look and what it needs to do in order to be a successful product. Once this has finished it goes to the CAD stage of the plastic parts design.

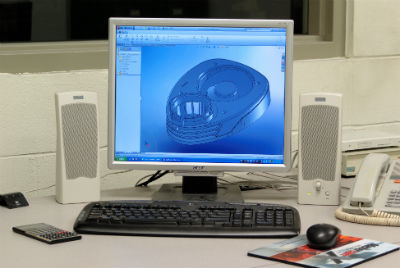

CAD

Inside of the computer, the part is designed three dimensionally. On the computer, it is not only possible to look at the item from all angles on the computer, but it can be put through tests in order to determine strength and if there are weak spots in the design. This way, it is possible to fix these problems ahead of time, instead of being forced to go out and product a physical item before discovering the problem. At the conclusion of the CAD process, the design is taken to the plastic injection molding team.

Producing the Mold

With the 3D design complete thanks to CAD, the mold is produced. This is what all future replications will be cut from during the injection molding process. The plastic injection company is able to assist with the creation of this mold in order to make sure it fits within the construction of the machine itself. After the first mold is produced, a test is performed in order to see how the final product comes out. When the first test injection molding is produced and it passes inspection, it is possible to continue on with the entire production and to start increasing the number of items manufactured.