The importance of heat sinks is not surprising. Thus, neither is the trendy practice of using plastics in lieu of traditional metals in their manufacture. Using custom plastics just makes sense, especially when one has concerns about transmission loss, production costs and thermal conductivity. How so and where does secondary machining fit in? Allow us to explain:

Benefits of Custom Plastics

The material is inherently cost-effective and efficient at reducing attenuation. Furthermore, like their metal counterparts, plastics come in various types, each with their own benefits. Among the types of plastics often used to create heat sinks are polyethylene (PEL/PEH), acrylics, PVC, nylon and epoxy, including glass fibre. Plus, as a whole, plastics have a thermal conductivity range that frequently runs from 0.17 (Epoxy) to 0.50 (PEH). So in a lot of ways they’re comparative to, if not better than, low-grade metals.

Plus Secondary Machining

Secondary machining adds more to plastics’ list of benefits in terms of design control. In the right hands, it may combat against organic variations in precision marks. And as we all know, for many industries a lack of consistency has the potential to be deadly. Furthermore, the benefits of secondary machining go beyond issues of precision and consistency. They also address the need for adaptability.

Equals an Unparalleled Combination

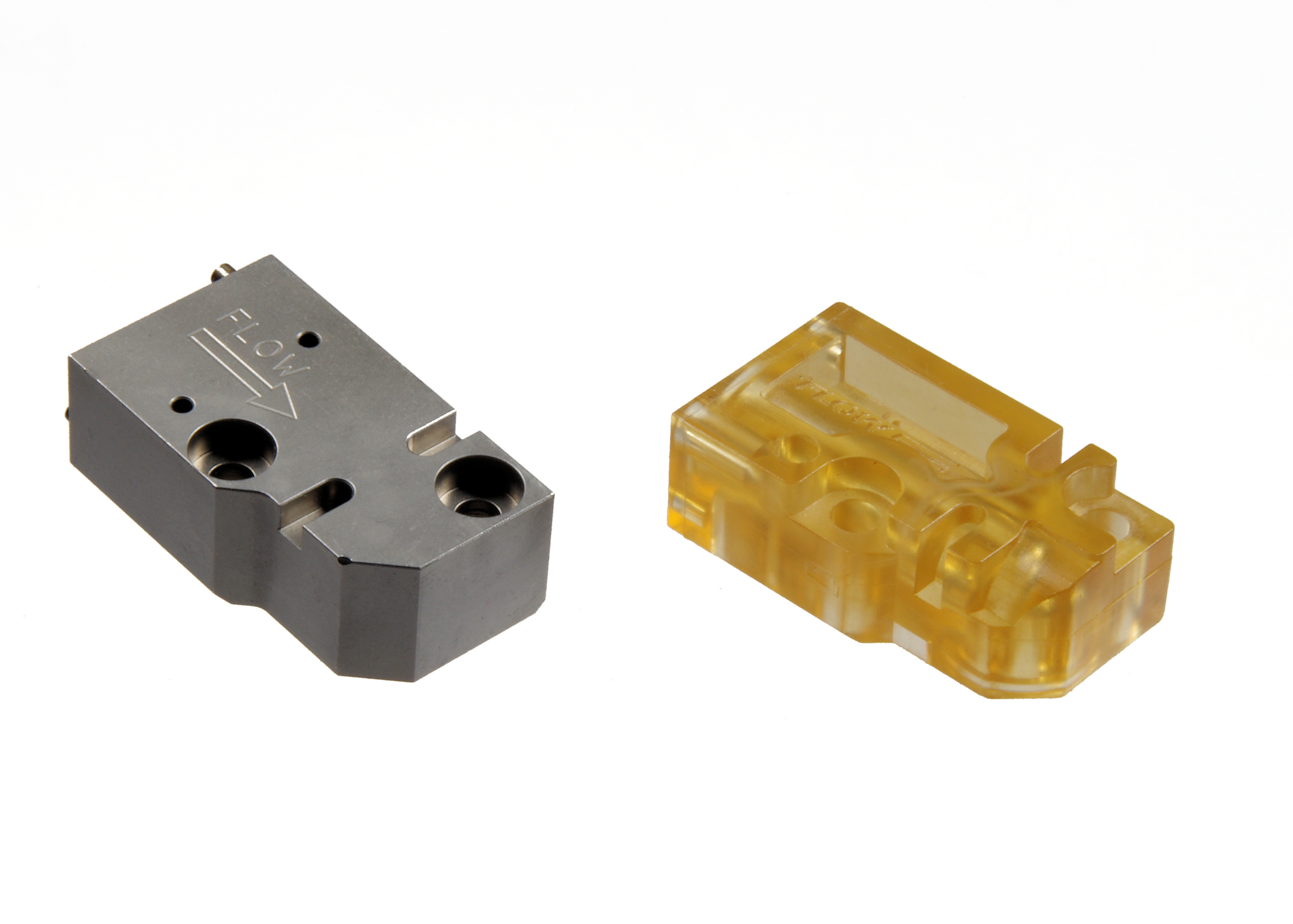

For example, secondary machining’s cost effectiveness makes it possible to create microchip enabled, custom heat sinks in less time than many competitors. Hence, outsourcing heat sink production to companies that specialize in all aspects of plastic part design and engineering is a smart move for those looking to quickly secure market dominance. This is most assuredly true when plastic parts companies offer add-on services, including those associated with metal-to-plastic conversion and real-time, supply chain management.

To learn more about secondary machining and how it may help your heat sink or microchip business get an inside edge, please contact Proto Plastics today. We are proud members of Tipp City’s Chamber of Commerce and their 2015 pick for Business of the Year.