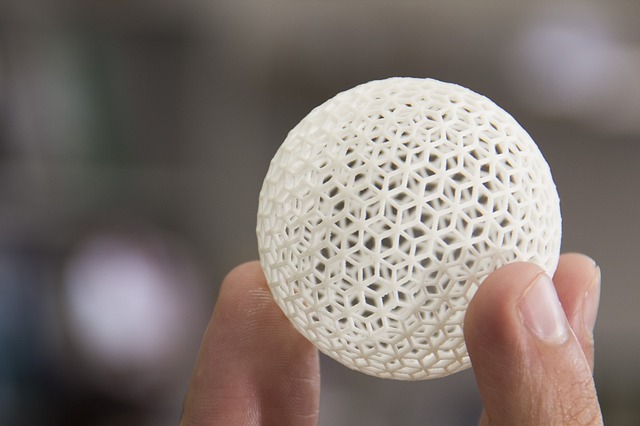

As many of you probably know, 3D printing is one of the newest fads in both engineering and enthusiast circles. Small machines designed to be given an AutoCAD design, processing it to move a head capable of extruding typically plastic, but a variety of materials have started being used, building up the requested object in layers over time. Generally regarded by engineers as an interesting tool with possibilities for the future, and the savior of mankind by enthusiasts, 3D printers can be a controversial topic. But is there any truth to the hype, or are they just a gimmick the average injection mold engineer can just pass over?

The most commonly talked about use of 3D printers is in the realm of rapid prototyping. Depending on the field of the engineer, they have started being used extensively to make simple proofs of concept and first or second drafts of designs to prove out new ideas. In this vein, is it possibly useful to 3D print prototypes of new plastic custom molding injection products before starting a design process to make a new mold? The pros are the same that have pushed other engineers to use them: fast turn around time on new designs, ability to make minor changes or possibly run multiple designs in parallel. However, current 3D printers won’t be able to make prototypes anywhere near the quality of custom molding injection products and in practice could quite possibly provide false data.

Could 3D printing ever be used to create new custom molds? Not any time soon, as the tolerances required for a custom mold are far beyond the capabilities of 3D printers, meaning that CnC machines will continued to be a requirement. But the same potential for proof of concept designs being made quickly and cheaply for potentially faster spotting of trouble spots in designs exists for molds as it does for the plastic products they are designed to make. Even if this process is never actually able to create a useable mold, it’s potential to help engineers reduce design time and testing costs is real.

Overall, 3D printers don’t appear to add much to the plastic injection molding design, test, and production processes at this time, but they are something to keep an eye on as they evolve.