Injection molding allows a manufacturing company to expedite the production process. It is possible to complete a single, finished product from the original mold in just a few seconds. Now, there are some variables at play here, but ultimately, no matter what is being constructed or designed, injection molding is able to assist and make sure it obtains a set standard. The casting process can be done under pressure in order to reach a deadline. While the process cannot be sped up, as it does take time for the plastic to heat and cool, the production can continue on for as long as possible, and without the need of much (if any) human interaction, the machinery takes over and can run 24 hours a day to reach any deadline. So, when a deadline is set and the manufacturing company is feeling the pressure, it is always possible to produce the required number of items with the help of injection molding.

Machines Do the Work

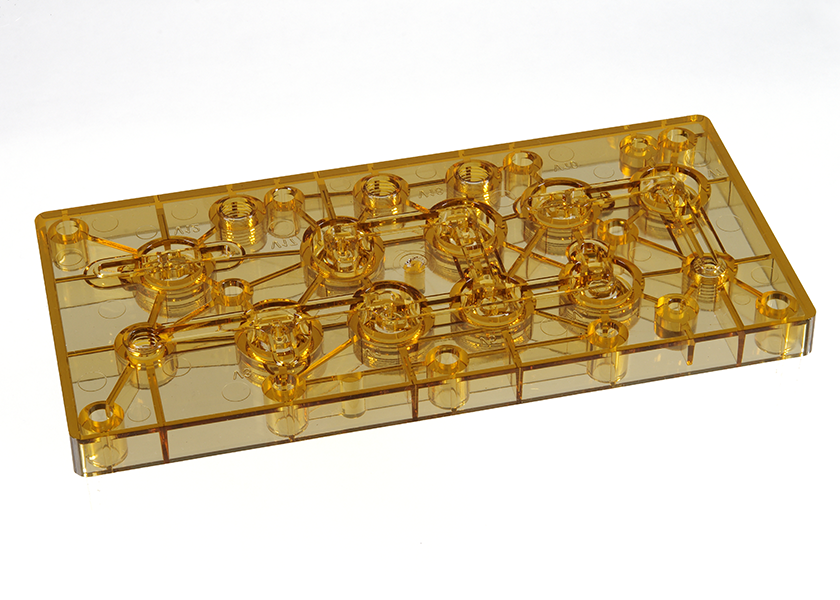

After the design and original mold is produced, everything else is handled by machinery. Plastic granules are deposited into a rotating barrel. The barrel is threaded like a screw so the plastic moves along the barrel to the tip, or the nozzle. Inside of the barrel, the plastic melts and, by the time it reaches the nozzle, is in liquid form. The plastic is injected into a mold through the nozzle. Once the mold is full it moves away from the nozzle and the interior product ejected out of the mold and cooled before the process starts all over again. None of this requires any kind of human interaction, so as long as the temperature is set correctly, production may run 24 hours a day, 7 days a week in order to reach any production requirement.

Variables At Play

Now, there are a few variables at play when it comes to this production. First, the amount of plastic required to fill the mold. Naturally, larger molds take more plastic to fill, which means it does take longer for the mold. Second, the kind of plastic is important to consider as well. There are generally seven different kinds of plastic commonly used during the production, with some thicker or thinner than others. The melting point for these different plastics vary, which again can alter production times, but it still can run 24 hours, 7 days a week.