To properly succeed, you’ve got to get things right first and foremost

You probably deal with lots of variables running your manufacturing business, and most of these variables change all the time. These variables include the cost of raw materials, labor, parts, shipping, and packaging, among many others. But you need to keep an eye on quality, even as these variables continue to change.

Your business will likely suffer greatly if you don’t get things right the first time – and all the time. Here are some of the consequences you’re likely to face if you don’t get it right:

Get things right or suffer loss of reputation

You could be doing everything possible from your end to ensure high-quality products or services for your customers. But are your vendors – the people who supply you with parts – doing the same? Poor quality raw materials, or parts, will definitely impact the quality of your final product; but no one will think about your suppliers.

If the quality of your final products changes for the worse, the damage it would cause to your brand would be enormous. Once you lose your reputation on the market, you may never recover. It’s important to get everything right as you engage your suppliers.

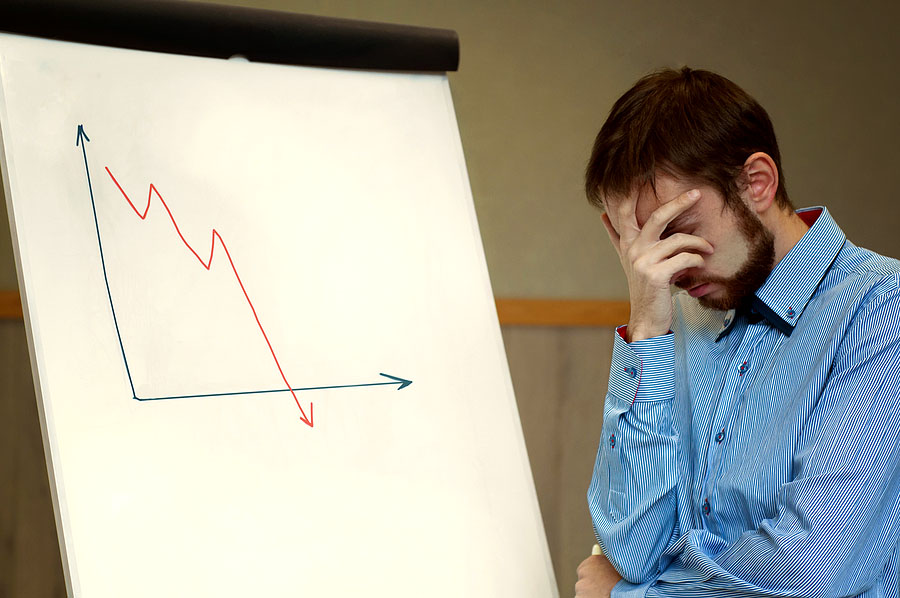

Get it wrong and have a decline in sales

One of the biggest and worst costs of not getting it right is a reduction in sales. If you get your variable wrong, it means the quality and quantity of your output will also be wrong, resulting in the loss of customers.

A constant decline in your sales can be your worst nightmare. This is because you need the sales to go right through the roof to keep your business alive, and meet its costs of operation. Reduced sales also mean less revenue, and you will face challenges meeting critical costs, such as labor.

Get things right or face possible legal repercussions

You could also face legal repercussions if you don’t get things right from the go. It’s even worse when you’ve been doing your best to get the best for your customers; but the shortcomings of your suppliers may get you into trouble.

If your final product harms the user, or fails to meet standards of quality and safety due to the use of substandard raw materials or parts, you’re likely to face legal heat. The fines, court charges, and legal fees may be too much for your growing business, and it may eventually collapse.

Risk of business collapse for getting it wrong

Getting it wrong with your variables may have far-reaching implications on your business, such as closure. If you lose your customers, have a damaged reputation, and are battling countless court cases, it will be a matter of when, and not if, your business would collapse.

It doesn’t matter how long you’ve been in business, or the size of your organization. Quality issues, and problems with balancing the variables, will likely drive your business into the ground faster than you would imagine.

High cost of production

If you factor in the variables, such as labor, shipping, and packaging, wrongly, you will likely have inaccurate figures on your hands. This means you will not get the expected output, and will have to readjust your variables.

For instance, you may have to purchase another batch of raw materials or parts because the initial batch has fallen short of your expectations. And you may never be able to compensate for the wasted time and clients lost because your products weren’t ready on time.

Proto Plastics can help

The cost of not getting it right when it comes to your variables can have a devastating effect on the sustainability of your manufacturing business. You need reliable suppliers, such as Proto Plastics, to ensure a steady supply of quality parts for your business. Contact us today for more information.