In the world of mechanical engineering, one often comes across terms like manufacturing and machining. It is natural to wonder what exactly differentiates the two manufacturing processes and which one to consider in a particular production process.

In short, manufacturing is a part of the entire gamut of production systems and comprises various additive processes. Machining, on the other hand, is a particular subtractive secondary manufacturing process and consists of functions like milling, turning, drilling, etc.

In this article, we discuss in detail what are the differences between manufacturing and machining and why manufacturing in general and injection molding, in particular, is more advantageous in nature.

Read on to learn more.

Manufacturing vs. Machining

What is Manufacturing?

As mentioned, manufacturing is a group of an additive production process. This essentially means that it takes certain raw materials or scrap items and convert them to useful mechanical parts or items as per the requirements. The inputs are both tangible like man, material, machine, money and intangible like planning and strategizing.

It must be noted that manufacturing is not any single process, rather it is a cluster of various processes like-

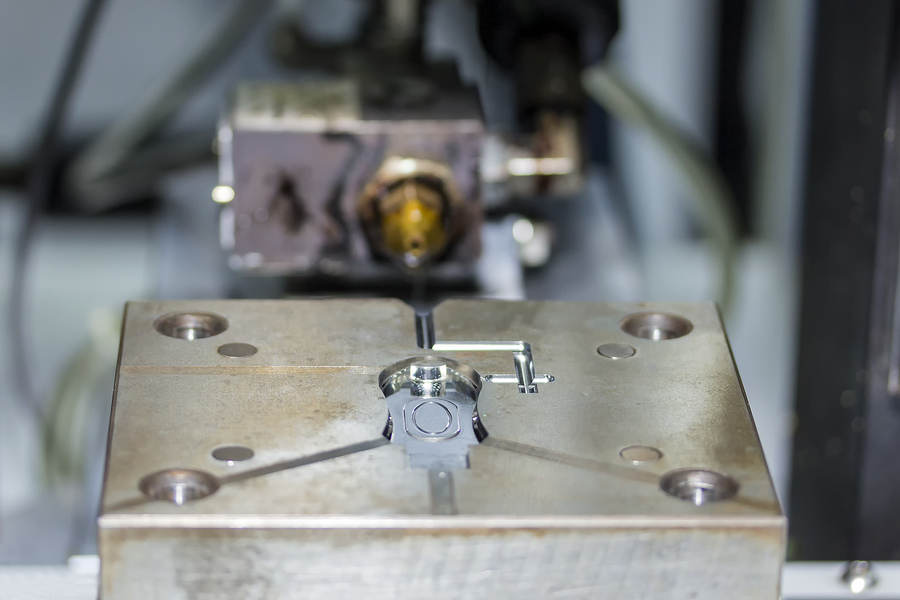

- Injection Molding

- Casting

- Rapid Prototyping

- Surface Working

- Forming

- Forging, etc.

What is Machining?

Machining is a particular secondary manufacturing process in which items are produced by removing excess material. The process starts with a preformed blank from which small sharp chips are sheared away by using various wedge-shaped cutting tools. Hence, machining is called a subtractive process.

Material is chipped away until the desired shape, tolerance, and size is achieved. Some methods used for machining are as follows-

- Milling

- Turning

- Slotting

- Drilling

- Facing, etc.

Advantages of Manufacturing- Particularly Injection Molding

Since manufacturing is an additive process, it offers certain advantages. These advantages are even better defined when we consider the specific manufacturing process of injection molding.

Let’s take a look at various pros of implementing additive manufacturing in general and the injection molding process in particular. All the below points apply to both the cases and have been elaborated from the point of view of injection molding.

1. Easily Produce Complex and Detailed Geometry

Manufacturing processes provide more control to shape and mold the raw materials into the desired shape. This allows complex designs to be converted from concept to production quite efficiently.

Injection molding, in particular, applies high pressure onto the molds, thus pressing the plastic inside harder against the mold. This high-pressure process makes it possible to add intricate design details to the final product.

2. High Efficiency and Better Speed-To-Market

After the ideation and initial testing of products are done, additive manufacturing processes like injection molding takes little time to carry out the production. This means that the actual process takes less time, thus improving the speed-to-market. At the same time, injection molding is a precise process that ensures a high efficiency of the entire system.

3. Better Quality and Strength

Components that have small moving pieces need stringent manufacturing tolerances and a controlled assembly system to ensure a minimum number of defects. Additive manufacturing processes are ideal for producing such intricate pieces without compromising on quality.

The injection molding process can additionally increase the tensile strength of the product by injecting fillers into the mold that provides extra strength to the finished piece.

4. Green Process

Manufacturing processes in general and injection molding process, in particular, produce a lower amount of waste when compared to other subtractive machining processes. In today’s era of environmental consciousness, businesses need to be green. Additionally, injection molding is lower on energy consumption when compared to other processes like milling or drilling.

5. Automation is Saving Cost

Most manufacturing processes like injection molding are automated. Most of the injection molding procedure is handled by automated programs and robotics with a single or few operators controlling the systems. This not only reduced the overall cost in terms of manufacturing and labor expenses but also ensure a higher degree of accuracy through the reduction of human error.

How Can We Help You

At ProtoPlastics, we have been offering high-quality custom plastic injection molding to our customers for more than 5 decades. We understand the requirements of our customers and fulfill them using our state-of-the-art facilities, superior designing services, prototyping and production systems, and our assembly line services. As an ISO 9001:2015 certified company, we guarantee our quality of service to our clients.

Contact us today to learn more about our services and offerings and know how we can help you with your needs.