Many companies and manufacturers use a metal because they assume it is the only solution. However, businesses around the globe are converting. Metal to plastic conversion is becoming considerably more popular because of being able to reduce the weight as well as the cost.

It’s important to understand the various benefits as well as the characteristics that can be achieved when it comes to plastic injection-molded parts.

Benefits of Metal To Plastic Conversion

There are quite a few benefits of metal to plastic conversion.

One of the most significant benefits is the cost reduction. The simple truth of the matter is that plastic is cheaper than metal. Whether you’re using steel, aluminum, copper, or any other metal, plastic is going to be a cheaper alternative. You can then pass these cost savings onto your customer or end-user.

Another benefit is that it is going to reduce the total weight. You may be looking at ways to reduce the weight of whatever it is that you’re creating by going with a hollow design versus a solid design. However, the easiest way to reduce the weight is to simply choose a lighter material – and plastic fits the bill. You may be able to offer a lighter weight model to customers or even increase its speed by eliminating some of the unnecessary weight.

Additionally, it’s possible to convert to plastic for the entire component or simply for an individual part. You can pick and choose based on what the project is and how it is constructed.

The Characteristics

Don’t assume that you can’t get the characteristics that you get in metal with plastic. For example, it’s possible to achieve an array of characteristics in the parts that are plastic injection molded:

- Dimensional Stability

- Noise Reduction

- High Impact Strength

- Electrical Conductivity

- Resistance To High Temperatures

- Resistance to chemicals

Are you shocked to learn of these characteristics that can be achieved with plastic? Many companies are, which is why it’s so important to do the research. A lot of new technology has made it possible to create durable parts and components with plastic injection molding.

As a result of the characteristics, more businesses are converting their metal parts to plastic ones.

How Does It Work?

When you are ready to convert from metal to plastic, you will identify all of the characteristics that are important to you. Engineering grade thermoplastic resins can be used to provide you with all sorts of highly sought after properties. In many instances, the thermoplastic components are superior to metal, especially because they are not going to rust or corrode.

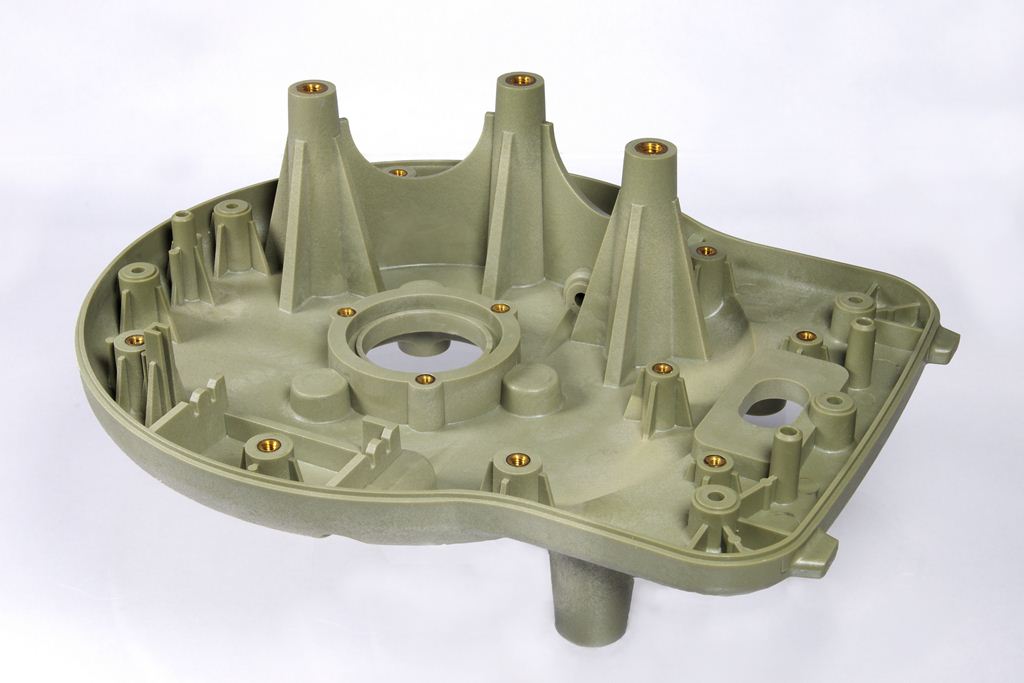

You will work with a contract manufacturer to determine the shape that the plastic needs to be molded into. All sorts of complex geometries and shapes can be molded. Many customers will rely on the manufacturer to assist with changing the design since the existing product may be made out of stainless steel. When this happens, it is important to adhere to the manufacturing principles while also going through various and extensive prototyping and testing.

It’s important to ensure that the end product meets all functional, mechanical, thermal, and structural requirements. If it is the final product as opposed to a single component, aesthetics may also need to be taken into consideration.

At Proto Plastics, we have the experience providing part design assistance as well is thermoplastic material molding. We have worked with many OEM customers to reduce weight and cost when producing parts that used to be made out of stainless steel.

Discover more about converting metal to plastic by contacting Proto Plastics. As a full-service contract manufacturer that produces custom, plastic injection molded parts and assemblies, we can provide solutions in an array of industries.