As a business person, you may have come across an opportunity to order custom plastic parts from a manufacturer. When outsourcing such plastic components, it is crucial to consider factors like parts tooling; this is the process of creating cost-effective plastic parts that are of good quality.

What is Plastic Part Tooling?

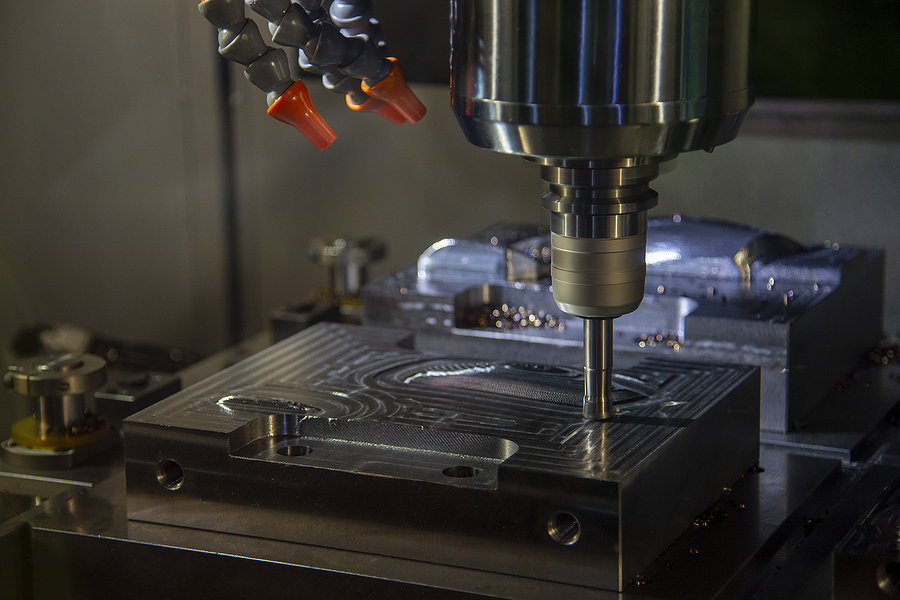

Plastic part tooling is a way of producing custom molds for plastic parts. The resultant components are affordable and functional since they are from custom-made steel molds, which shape liquid plastic within the injection molding machine. The finished plastic parts also have a precise fit and surface finish.

Tooling Options

There are several types of tooling options, including:

- Plastic Injection Molds. This type of tooling is ideal for mass-producing plastic parts. It begins with custom steel molds placed within the injection molding machines. The machines inject melted plastic into these molds. Upon completing this process, each part is removed from the mold by placing it in hot water. Plastic Injection Molds is one of the most economical options with the shortest lead times.

- Plastic Blow Molds. It is similar to injection molds, except that compressed air or gas blows into a piston to push each plastic part out of the mold. Besides, Plastic Blow Molds is a budget-friendly option because it is faster than other types.

- Plastic Compression Molds. This tooling type includes custom steel molds placed inside a hydraulic press to pressurize and shape heated plastic.

- Steel Framing. This option for tooling uses sheet metal, which creates a rigid frame onto which manufacturers attach the steel molds. It is simple, and manufacturers can customize it to design various kinds of the finished part.

- Steel Blank Molds. As a tooling method, it also uses steel molds, but has no moving parts. It is mostly employed in creating plastic injection molds or blow molds.

What Are The Benefits Of Plastic Part Tooling?

There are countless advantages to plastic parts tooling. Some of the major ones include:

- Fast delivery. Creating custom molds for plastic parts is a quicker process than other methods. It means you get the exact part you need in the shortest time possible, sometimes in as little as ten days, depending on the complexity of the part in question.

- Low cost. The process itself is lucrative because you do not create new molds for mass quantity parts. For this reason, you save money and also avoid making costly mistakes that would require new molds for one or two defective components.

- The molds created with the tooling technology are quite versatile. When you utilize them, you are able to generate multiple parts of different shapes or sizes from a single mold.

- Increased accuracy. Having plastic parts tooling can help you attain increased precision. This aspect ensures that you get high-standard finished products.

- Improved quality. Tooling offers much better quality parts compared to DIY methods. What this means is that the finished product is not only accurate, but also of superior quality.

Where Can You Outsource Plastic Part Tooling Services?

At Proto Plastics, we provide you with high-quality plastic parts tooling services that will enable you to get the exact part you need. We are a contract manufacturer offering full-service assemblies and custom plastic injection molded parts. We specialize in close tolerance and technically demanding parts that are essential in various industrial sectors.

Likewise, we offer a wide range of tooling capabilities and options. Contact us today to get a cost estimate of your plastic parts tooling and learn more about our services.