A Top Injection Molding Company

We pride ourselves in providing the highest quality injection molded parts to our customers using a collaborative process that focuses on customer success and satisfaction. Our commitment to quality is supported by our industry certifications and experience.

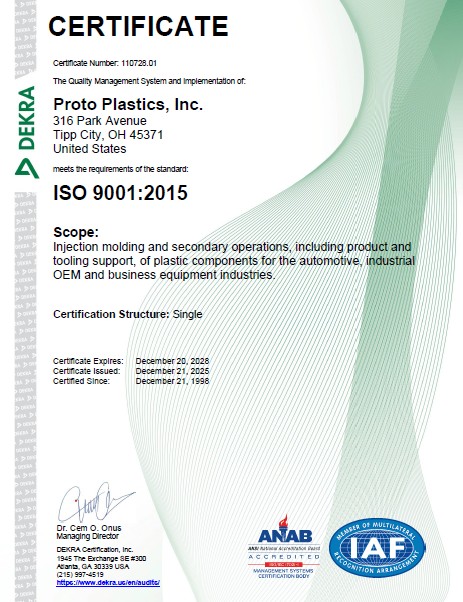

Proto Plastics has invested heavily in our total Quality Management system. We are a Preferred Supplier to a number of major manufacturers who have zero tolerance for non-conforming parts and materials. Our technical staff has an in-depth knowledge of ANSI standard Y14.5 (GD&T) and extensive experience, training and capability in mechanical inspection. We continually meet and exceed the procedural and documentation requirements of ISO-9001:2015.

Inspection of Incoming Materials

All purchased products that are incorporated into Proto Plastics final products are subject to a detailed technical Quality Control (Q.C.) inspection. Material certifications are kept on file for all incoming shipments of thermoplastic resins.

New Part Qualification

Before a new part can be released to production, it goes through a qualification process that varies in intensity depending on customer requirements, engineering complexity and quality constraints. The qualification methods may include some or all of the following:

- First Article Inspection

- Process Capability Study

- Pre-production runs to produce a limited number of samples

- Production Part Approval Process (PPAP)

- ECN Release to Production after customer approval

Production Monitoring & Verification

Throughout the production cycle, plastic injected molded components and assemblies are checked to verify their compliance with all required specifications. Typical verification and inspection processes include dimensional, functional and/or destructive tests.

Measurement & Testing

Our Inspection Lab features state-of-the-art equipment to ensure compliance with the most demanding part and assembly specifications and tolerances:

- Brown & Sharp Microval Coordinate Measuring Machine (CMM) with Quadra-Check 5000 3D software

- OGP Optical Comparator with Smart Edge Detection

- Additional standard measuring/testing devices such as calipers, micrometers, thread & height gages, surface plates, etc.

Monitoring of the Quality System

To ensure compliance and continual improvement, our quality assurance system is monitored through a variety of techniques, as appropriate for a particular process and its importance. These include:

- Conducting internal audits of the quality system

- Monitoring trends in corrective and preventive action requests

- Analyzing product conformity and other quality performance data and trends

- Measuring and monitoring customer satisfaction through periodic surveys