There’s no Replacement for High-Quality Results

We’ve been injection molding plastic parts for more than a half-century. We create value for our customers by combining experience and expertise with an innovative, collaborative approach.

Proven Results

-

Enlarge Image

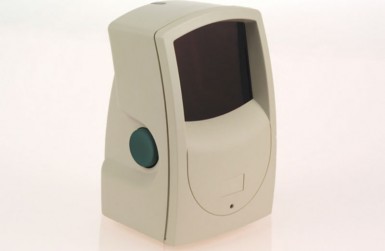

Water quality testing device

Sophisticated part design & multi-part assembly

-

Enlarge Image

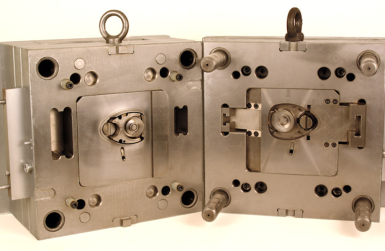

Single-Cavity tooling

Quick-turnaround, Quality tooling

-

Enlarge Image

Ultrasonic Welding

Used for the bonding of thermoplastic parts and for putting inserts into plastic molded or machined parts.

-

Enlarge Image

Agricultural pump housing

Super high-strength Nylon application

-

Enlarge Image

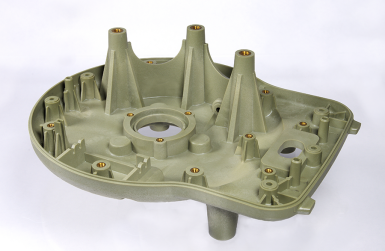

Construction housing base

Metal-to-plastic conversion & cost reduction project with several ultrasonically welded inserts

-

Enlarge Image

Battery cover

New overmold application to fix existing housings

-

Enlarge Image

Medical device charging housings

These parts are injection molded, pad printed, & insert overmolded.

-

Enlarge Image

Sensor housing

High-temperature application

-

Enlarge Image

Fuel cell housing top

Very complicated tooling; product used outdoors

-

Enlarge Image

Laser leveling housing

Sub-assembly with pad printing

-

Enlarge Image

Laser leveling construction housing

Project included over-molding, sub-assembly, & pad printing

-

Enlarge Image

POS scanning device

Multiple-component sub-assembly