Metal to Plastic Part Conversions

Do you have a metal-based product that is a good candidate to move to a plastic injection molded part? Proto Plastics Inc. works through this process with several of our OEM customers. Whether it’s for weight, total component, and/or cost reduction purposes, we can help you realize the benefits that come along with converting metal parts to plastic injection molded parts.

- Resistance to high temperatures & chemicals

- Electrical conductivity

- High impact strength and durability

- Noise reduction

- Dimensional stability & close tolerances

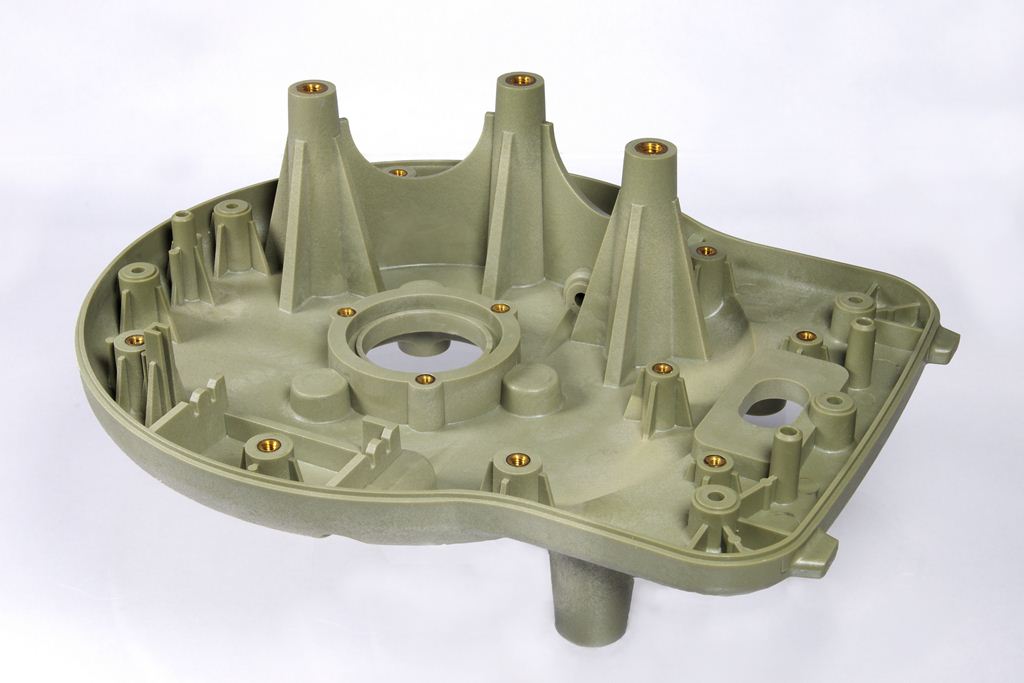

A large OEM customer within the printing industry asked us to partner with them to change the design of an existing product [which was made out of stainless steel] in order to reduce weight and cost. The necessary research was conducted so that a suitable thermoplastic material could be selected and utilized for the application. Then the appropriate design changes were performed, while adhering to plastic injection design and manufacturing principles. The part made it through extensive prototyping and testing, being able to meet functional, thermal, mechanical, structural, & aesthetic requirements. The project was viewed as a success since it was able to deliver a 10X cost reduction.

Proto Plastics has significant experience in providing the thermoplastic material and part design assistance required to help you meet your demanding product requirements. Please contact us when you need support for your metal to plastics conversion project.