The 3D printing process is still relatively new given that it has only been on the scene for about five years. Its novelty combined with misconceptions of its present capabilities has generated a lot of interest in it as an alternative to plastic injection molding.

Differences Between 3D Printing and Plastic Injection Molding

These two processes are similar in many ways. For example, they are both used to create complex shapes from plastic; however, it is also important to note the differences. Those differences include:

- Costs

The upfront cost of 3D printing is low, but has the potential to go up due to misprints. The cost of injection molding is relatively high at first but that cost goes down over the course of a high-volume production run.

- Technical Issues

Software glitches continue to plague 3D printing but do not affect injection molding. Fixing these issues is often costly and time-consuming.

- Time

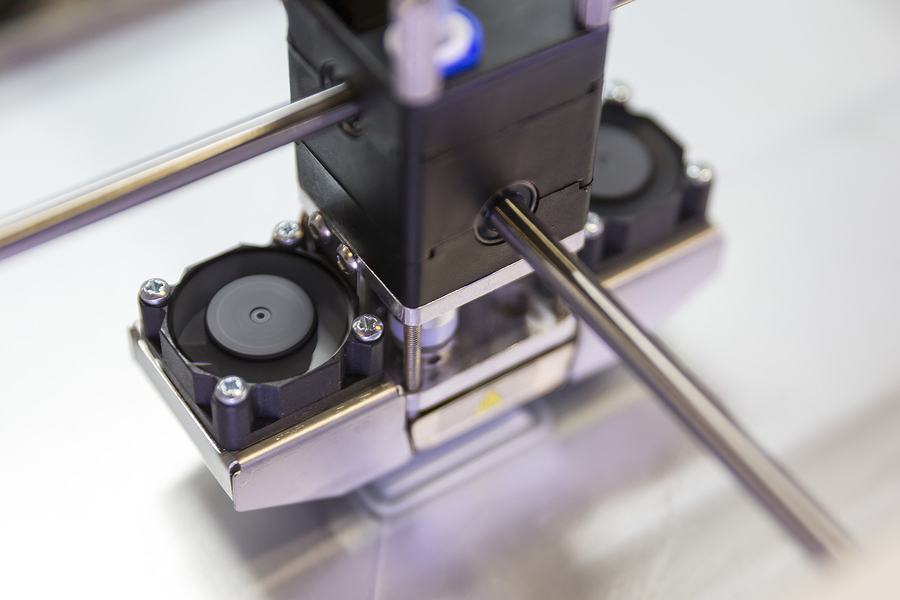

Injection molding involves injecting polymers into a mold and then rapidly cooling them so that another cycle can start. Conversely, the fused deposition modeling type of 3D printing requires that a plastic filament be melted and used a drop at a time to make the printed item. This can take hours. The result is that plastic injection molding is a much faster option.

- Quality

The number of 3D printable materials is still limited when compared to the number used for injection molding. Parts that are 3D printed will therefore not have the same properties as injection molded parts. For instance, injection molded parts will have tighter tolerances when compared to 3D printed parts.

Those differences are why most manufacturers choose plastic injection molding over 3D printing for serious production. At Proto-Plastic, our expert staff can help to ensure a smooth manufacturing process and a quality finished product. Contact us to learn how we can meet your needs.