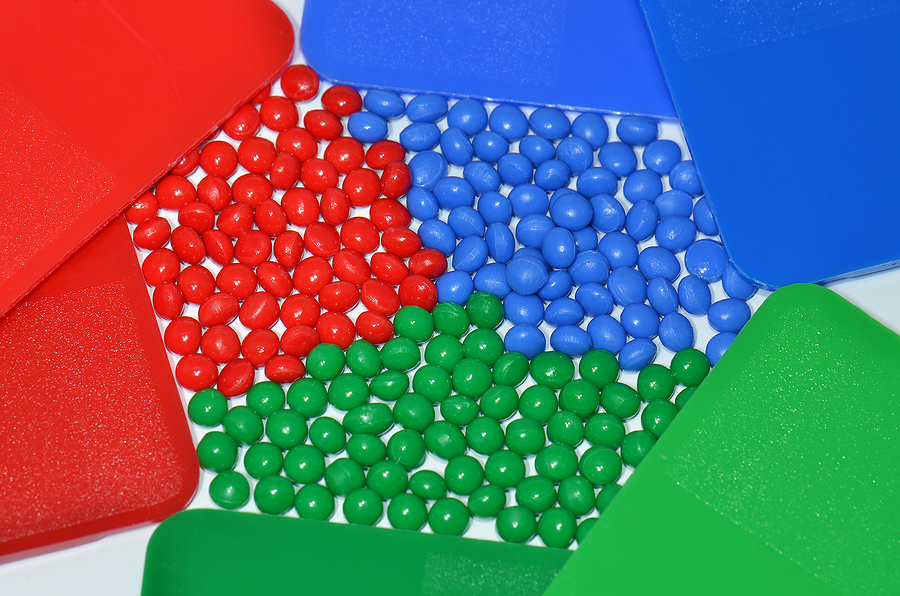

We examine colors best used in plastic injection molding for vibrant, attractive products with high color strength

The plastic color used in plastic injection molded products starts as whitish or clear. But if the custom products produced by the injection-molded plastic process requires color, whether it be for safety, color coding, or just cosmetic reasons, pigments need to be added to the process to produce the desired color.

All types of color pigments can obviously be added to the process. Organic and inorganic particles can be added to a polymer base.

Organic pigments are hard to disperse and have a tendency for the pigment particles to clump and can cause spots and specks in the final product. These examples are used mainly for color strength, or the conservation of color for a longer time when mixed with white, and brilliant shades.

- Polycyclics

- Mono- and Di- Azo

- Heterocyclics such as Isoindoline and diketopyrrolopyrrole (DPP)

- Macrocyclics such as Phthalocyanine

- Metal complexes

Inorganic pigments are more easily dispersed throughout the plastic. These pigments are used when opacity or the lack of transparency is desired. They are stable when it comes to heat, light-resistant, and can stand up to weather. Some examples of inorganic pigments are:

- Metal oxides like iron or chrome oxides.

- Sulfides like Cadmium Sulfide

- Carbon black.

- Titanium dioxide: The most widely used pigment in the plastic industry

- Bismuth Vanadate

Stretching & Bending

According to engineerdog.com, stretching and bending the plastic product can cause a “crazing” effect. This is when the color molecules are stretched away from each other, causing voids and various size holes, which turns the color of the area permanently white. Stretching and bending the product can also cause the color to fade or produce a hazing effect.

To reduce any impact, stretching, or bending causes of discoloration, different types of color would have to be tested with a particular plastic product to determine which would work best. There are other factors, besides color, that can contribute to crazing, fading, or hazing such as the thickness of the product, the type of resin selected, and material choice.

UV Exposure Inside & Outside

Light fastness is the measure of whether a color will fade or how fast it will fade when the product is used for indoor applications under indoor UV exposure or outdoor applications under outside UV exposure.

Weathering & Heat

Some custom plastic products, which will be used in outdoor applications, will need the application of weather and heat-resistant pigments to resist color fading and alteration.

14 Most Vibrant Colors For Injection Molded Products

- Organic pigments:

- Yellow: Isoindolinone

- Medium to high color strength.

- Excellent light fastness.

- Excellent heat and weather resistance.

- Orange: Isoindolinone

- Medium to high color strength.

- Excellent light fastness.

- Excellent heat and weather resistance.

- Red: Diketopyrrolopyrrole (DPP)

- High color strength.

- Wide range of opacity.

- Very pure and brilliant shade.

- Good to excellent light fastness.

- Good to excellent heat and weather fastness.

- Blue: Phthalocyanine

- High color strength.

- Good light fastness.

- Satisfactory heat fastness.

- Good to excellent weathering.

- Violet: Quinacridone

- Medium to high color strength

- Good light resistance

- Satisfactory heat resistance

- Good to excellent weather fastness

- Green: Phthalocyanine

- High color strength

- Good light fastness

- Satisfactory heat fastness

- Good to excellent weathering

- Brown: Diazo pigments

- High color strength

- Wide range of shade or opacity

- Good light resistance

- Satisfactory heat resistance

- Medium to good weathering

- Yellow: Isoindolinone

- Inorganic pigments.

- Yellow: C.I. Pigment Yellow 184

- A Bismuth Vanadate compound

- Heat-resistant from 240 to 300 degrees Celsius.

- Excellent light resistance

- Excellent weather resistance

- Orange: C.I. Pigment Orange 20

- A Cadmium Sulfide.

- Heat-resistant from 400 to 600 degrees Celsius.

- Red: C.I. Pigment Red 101

- Iron oxide.

- Heat-resistant up to 300 degrees Celsius.

- Excellent light-fastness

- Blue: C.I. Pigment Blue 29

- Heat-resistant from 300 to 400 degrees Celsius.

- Good light resistance

- Violet: C.I. Pigment Violet 15

- Heat-resistant up to 250 degrees Celsius.

- Excellent light resistance

- Green: Pigment Green 17

- Chrome oxide.

- Excellent light-fastness

- Brown: C.I. Pigment Brown 31

- Chrome/Iron oxide

- Up to 300 degrees Celsius of heat resistance

- Excellent light-fastness

- Yellow: C.I. Pigment Yellow 184

Contact us for your engineered solution to your injection molded plastic products.