When designing plastic parts that will be injection molded, you might have questions about design criteria. For example, what draft angle ensures the part’s easy ejection from the mold.

Below is a guide to the most common criteria for designing plastic parts.

Wall Thickness

The wall thickness of a thermoplastic part depends on several factors. These factors include the type of thermoplastic used, mechanical stresses on the part, electrical property requirements (if any), etc.

The following are general rules of thumb:

- The part’s primary wall thickness should be uniform

- Avoid quick thickness transitions. Instead, use gradual thickness transitions of 3 to 1.

- Gating, where the injection of the thermoplastic occurs, should be in the thicker section

Wall Thickness Considerations

When designing plastic parts, several factors should be considered, determining the part’s wall thickness. These factors include:

- Application requirements such as:

- Structural strength

- Fatigue

- Deflection

- Electrical loads

- Moldability of the part includes

- Part size

- Material flow to the narrowest part

- Number and location of gates

- Design requirements for registering agencies such as UL or RTI

Parting Line

The part’s design should include considering the location of the parting line, also called a part line. The design of the part should also have the draft (angle of perpendicular components) and shutoff.

The location of the parting line should occur at a major feature plane. When a step parting line is required, a 7° draft angle is preferred, 5° minimum.

Radii and Fillets

The inside radius of a corner (r) should be 25% to 60% of the wall thickness. The outside radius of a corner (R) is the sum of the inside radius plus the material thickness (t). R = r+t.

The fillet radius is the same as the interior radius, with a minimum of 0.020 inches (0.508 mm). If the feature is load-bearing, a larger radius is required.

Sharp corners should have a break of at least 0.005 inches (0.127 mm).

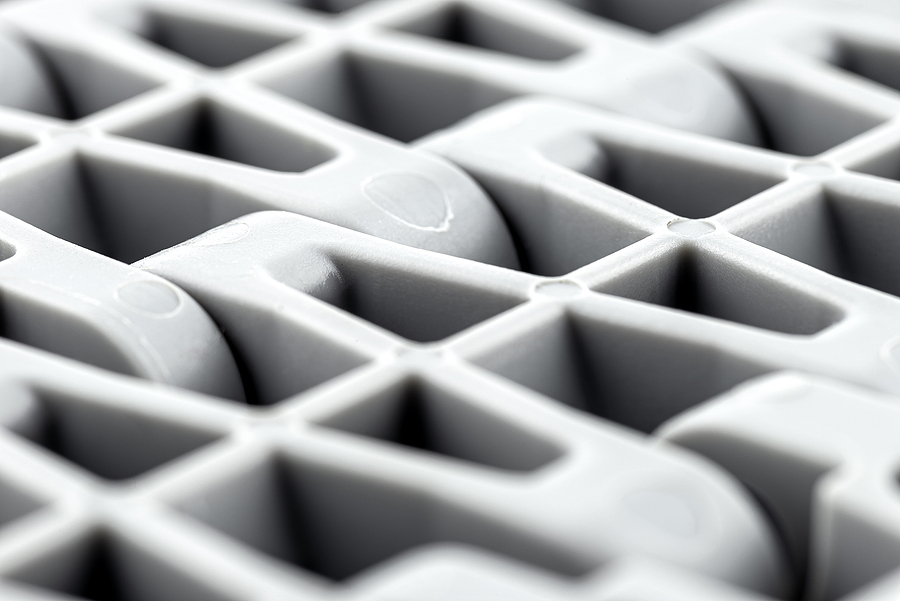

Ribs

The thickness of the rib where it intersects the wall should be 50% – 60% of the wall thickness, with a fillet radius of 0.015 inches (0.381 mm). The maximum height of the rib is 3x the wall thickness.

The typical draft of a rib is 1° to 1.5°, with a minimum of 1/2° per side.

The minimum spacing between the ribs is twice the wall thickness.

Gussets

The recommended thickness of a gusset at the wall is 50% of the wall thickness.

The gusset height maximum is 95% of the height of its attached wall. Typically, the gusset height is less than four times the wall thickness, preferably two times the wall thickness. The fillet where the gusset meets a feature or wall has a radius of 25% of the wall thickness.

The spacing between gussets should be at least two times the wall thickness.

Bosses

Usually, the outside (OD) diameter is two times the inside diameter (ID). The boss’s base should be less than 60% of the wall thickness, and the maximum height of the boss is three times the OD. The boss’s radius at its base should be 25% to 50% of the wall thickness, with a minimum radius of 0.015 inches (0.381 mm). The bottom of the core should have a radius of 0.010 inches (0.245 mm).

The minimum draft of the OD is 1/2°. The draft of the ID is 1/4° minimum.

Bosses positioned near an external wall should be placed a minimum of 0.125 inches (3.175 mm) inboard from the wall to the OD.

The minimum space between two bosses is twice the wall thickness.

Bosses for Fastener

For a boss designed for fasteners, consider the following additional suggestions for designing plastic parts:

- The boss ID should be 0.8 times the screw diameter

- The screw engagement – 2 1/2 times the screw diameter

- The core hole depth – 0.032 inches (0.813 mm) plus screw engagement length

- Chamfer at the top of the boss – recommended for screw lead-in

Holes and Depressions

The following are guides for designing holes and depressions in a thermoplastic part:

- Blind cores –

- Hole ID ≤ 3/16 inches (4.763 mm) – height < 2 times hole diameter

- Hole ID > 3/16 inches (4.763 mm) – height < 3 times hole diameter

- Through holes –

- Hole ID ≤ 3/16 inches (4.763 mm) – height < 4 times hole diameter

- Hole ID > 3/16 inches (4.763 mm) – height < 6 times hole diameter

- The spacing between two holes or one hole and the edge –

- Twice the wall thickness or twice the hole diameter; whichever is greater, as a minimum.

While this guide gives the basic design information for injection molded parts, not all plastics have the same design criteria. For example, structural foam thermoplastics have different requirements and refer to the design specifications for the specific thermoplastic used.

Contact us for more information about designing plastic parts.