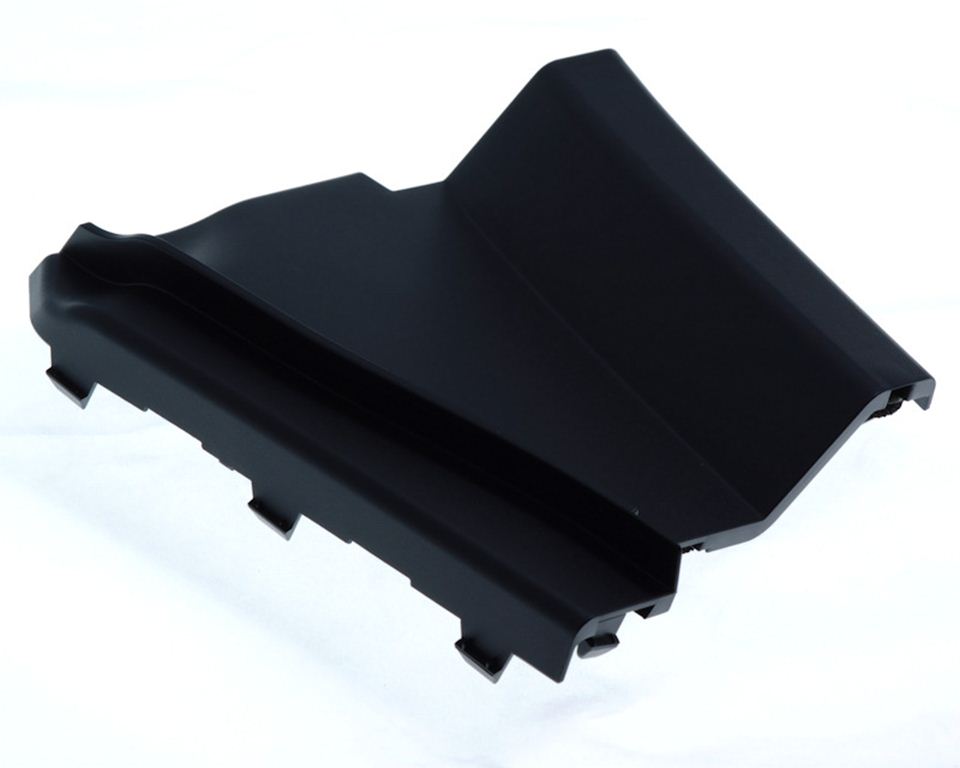

For anyone working with plastic injection molding, the most common development problem remains sink marks. These are areas in the plastic that appear like dimples, with small depressions inside of the plastic. Like craters, these depressions reduce the structural strength of the plastic, all while looking off-putting as well. Plus, there are many fields of plastic injection molding where sink marks are simply going to render a particular product useless. So, for an injection molding company, it is necessary to both troubleshoot the reasoning and go about doing everything it can to minimize the marks in the finished product.

Too High Barrel Temperature

While it is important to melt the plastic for injection, it is possible for the barrel temperature to be too high. When this occurs, the resin absorbs a large amount of the heat, which causes an increased size of the surrounding, voided area between the plastic molecules. Due to this, the resin closes up upon cooling and leaves a large void for the cooling molecules to fill, causing the sink marks. To correct this, it is necessary to decrease the barrel temperature to allow the molecules the ability to expand normally and offer a more consistent shrinking when cooled.

Poor Injection Pressure

The pressure of the injector must be high enough to push the melted material into the mold and through all runners and gates. If the injection pressure is inferior, parts are going to start to cool before the rest of the plastic is in place. This creates an unnatural bond in the plastic and results in sink marks. Increasing the injection pressure in order to reduce the time it takes to fill the mold can correct this.

Cooling Time

Cooling time is very important. The product must cool and eject from the mold in a solid state in the right time, otherwise it can cause sink marks and other problems. If the cooling time is short, the skin is not going to dry and become thick enough to stand on its own, causing it to fall apart upon ejection and too long of a time causes the plastic to stick, resulting in sink marks.

Now, it is very important to understand that it is not always directly apparent as to which problem is causing the sink marks, so it is necessary to experiment with one alteration at a time until the sink marks are removed.