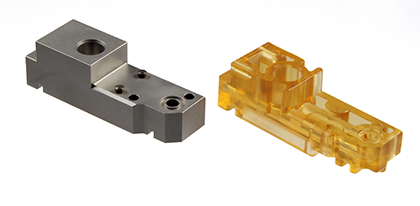

Save Money by Converting

Save money by reverse engineering your existing metal parts with plastic parts tooling. High performance plastics replace metal, with the following benefits:

- Lighter weight means lower shipping for you and your customers

- Easier shaping of all types of parts with plastic injection molding

- Faster production means you fill your orders faster

Will plastic cost less than metal?

While it’s hard to say without reviewing your specific project, plastics can also cost less than metal, in addition to the benefits mentioned above: lighter weight, easier shaping, and faster production.

High performance plastics and resins vary in cost, and this is where expert engineering comes into play: to review your project in detail and find all possible savings for you when engineering a metal to plastic conversion.

Is plastic as good as metal?

Contemporary plastics are as good or better than metal for many parts. They are durable against high temperatures and the effects of chemicals, they can conduct electricity, resist high impacts, reduce noise, and be precisely engineered.

How much will mold tooling cost?

In our experience, conversion costs pay for themselves when done carefully and conscientiously by experienced engineers. Then, the rest is savings for you: a superior part at lower cost for as long as you need.

Contact us today to find out more about metal to plastic part conversions. Much depends on the level of expertise you choose when selecting a company to handle your project. At Proto Plastics, we look forward to hearing from you soon!