With over forty years of experience, highly trained tooling engineers, mold makers, and technicians, Proto Plastics is the answer for your plastic parts tooling needs. Our customers include a wide range of industries and agencies including automotive, medical, telecommunications, construction, the defense department, and many more. And most of these loyal customers have done business with Proto Plastics for ten years, some as many as thirty years. Our rating boasts a 4.6 out of 5 from our customers.

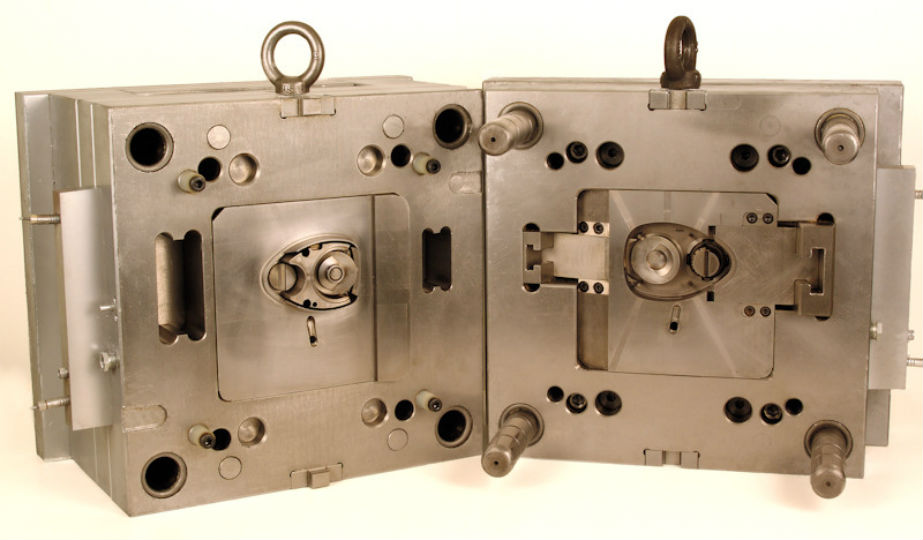

Our in-house tool design and building facility utilizes state of the art equipment such as our CNC Machine and our Star Automation Machine. Proto Plastics has the capabilities to convert existing metal molds into high quality plastic parts with your budget and turn around time in mind. And, if needed, we are able to machine only the cavity and core portions of the mold. We will work with you as a team to modify an existing mold and tool it to your specifications with precision, function, and economics as our service goal to you. We offer tooling in single, family, and multi-cavity configurations.

Proto Plastics range of services to our customers gives us the experience to help you design, construct, and maintain your molds. Our inventory is full of proprietary based MUD frames and we proudly guarantee our work to you. We are single sourced and the majority of our work is done in-house. When the occasion arises, we do outsource to trusted partners for tooling assistance. Please feel free to contact us to request a quote or to answer any questions you may have.