The use of plastics has a history dating way back in the 1800s when the need to replace such materials as tortoise shells, bones, iron, ivory, and gold rose. Their scarcity led to the discovery of the first plastic material whose composition was cellulose from trees mixed with some chemicals. Many people prefer plastics because they are malleable and recyclable.

Types include Polyethylene Terephthalate, High-Density Polyethylene, and Polyvinyl Chloride, among others. Here are some factors worth considering when seeking to identify quality plastic parts.

Type of the material

Different plastics differ in the chemical configuration of the material. The company or individual sourcing – the parts must consider the type which determines the thermal stress the part can endure when it is in use ordinarily and optimally. What the parts constitute is also a crucial element of consideration because it determines its cost as well.

Application

Resistant plastics are best for areas where movement, as well as the use of chemicals, is common. Such varieties as Polyvinyl Chloride, are poisonous hence, you need to ensure there is no contact between these parts and anything edible. For that reason, such plastic parts are not suitable for use in food processing industries. They are however appropriate for external use.

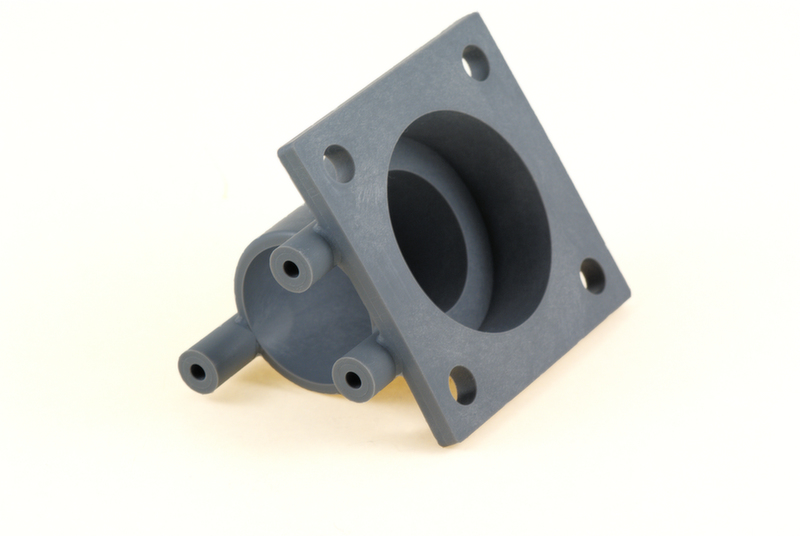

Unique features

Since plastic parts are not as resistant as those made from metals, one should consider designing them with unusual features like holes and undercuts. For instance, if the part is for use on a mold, ejecting the plastic part with ease is a necessity because forcing it out, can destroy it. Contact us now for more information.