Proto Plastics has been in the injection molding and design business for over fifty years. Our managers and supervisors have been with the company for an average tenure of nineteen years; many other employees have been with us for more than twenty years. We take pride in being able to provide excellent service and advice about what potential customers should expect from a plastic injection molding manufacturer. Here’s an overview of how our injection molding capabilities will satisfy all of your needs and deliver products of the highest quality.

Proper Component Sourcing

Any good construction is built on the foundation of solid materials. If mistakes are made during the component sourcing process, then the process of the production will be fundamentally flawed in a way that cannot be corrected. Materials not obtained from the correct suppliers will result in lower quality products, more difficulty in complying with regulations, while increasing the cost and lead times of the production.

In order to avoid such a situation, Proto Plastics treats the role of component sourcing with considerable care. We only buy standard and customized parts from suppliers that meet our ambitious standards. We heavily scrutinize them to ensure they deliver high-quality parts. Then we assemble the quality components procured to meet specified customer needs.

Mold Availability and Suitability

Injection molding techniques allow for making several types of products and applications. It’s important to know the injection molding manufacturer is adept enough to handle whatever work is thrown at them. Proto Plastics is such a company. We own nineteen injection molding presses, including several Roboshot electric injection molding machines. The presses range up to 440 tons, which enables us to handle a vast range of part applications.

Inside each press is a microprocessor-controlled Cincinnati Milacron machine, which gives us a level of repeatability and flexibility in press scheduling, as well as the ability to quickly react to customer changes. Operating on a two shift basis is the norm for us. This method minimizes unnecessary press shutdowns and startups and lowers our operating costs. It also allows us to retain our capacity for high volume requirements.

With these machines and our longstanding expertise with injection molding techniques, Proto Plastics has been able to produce insert molded and overmolded component parts, including plastics, windows, bushings, shafts, stampings, screw machine parts, inserts and electro-mechanical parts. Insert molding and overmolding are highly efficient methods of reducing assembly and labor costs, increasing reliability, and improving design flexibility.

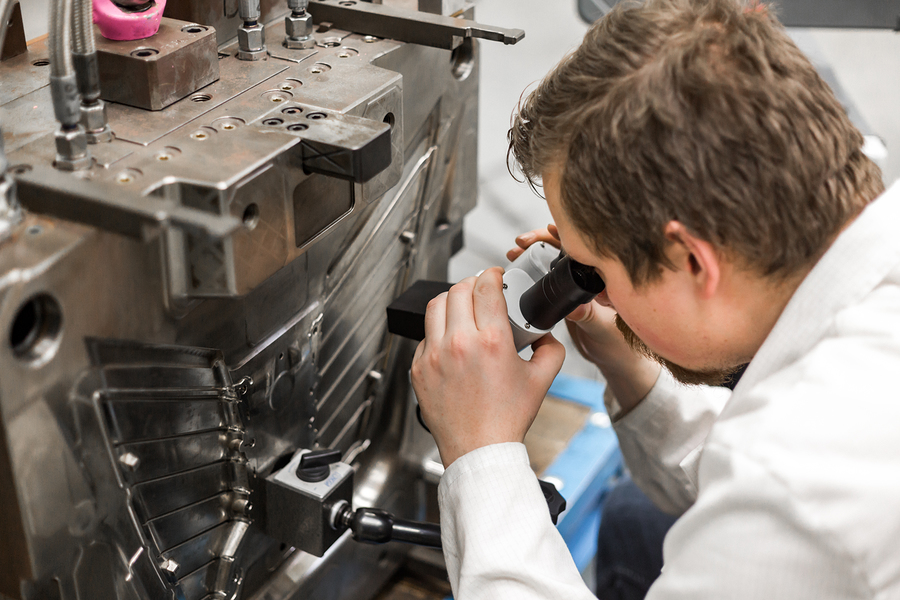

A Strict Attention to Detail

Being able to consistently provide quality products is crucial to our business and our customers; as is the ability to do so on a reliable schedule. Poor planning can lead to significant problems in the supply chain (increased costs, customer dissatisfaction, and unwanted delays) that severely harm your reputation in ways that can take ages to reverse. At Proto Plastics, we prioritize sticking to firm deadlines and completing our projects on time.

We were one of the first companies to fully implement an IQMS ERP system that acts as a hub for all data related to order entry, scheduling, quoting, inventory control, purchasing, labor reporting, billing and accounting. We control and schedule all of our plastic injection molding production presses through the RealTime Machine Monitoring module. Supervisors view every aspect of press operation as it happens, spotting and correcting small variations before the production completes. This system makes the fine details which complete every customer order easier to find.

High-End Efficiency

Our level of automation further burnishes Proto Plastics’ dedication. The presses operate in automatic mode for as long as possible in order to increase productivity. Robotics or conveyor systems remove finished parts from the injection mold. These processing decisions result in a steady, efficient, and cost effective system that improves the injection molding process. At the end of the process, our technicians inspect and test the products before releasing them. We refuse to put out any work that hasn’t met all of our expectations.

Choose Proto Plastics For All of Your Manufacturing Needs

With Proto Plastics, rest assured everything takes place in order to provide whatever molding solutions you require. We treat our clients as collaborators so that the designs can reach the highest possible standards. If you are interested in working with a top-notch injection molding manufacturer, or would like to know more about injection molding, please contact us here.